Why a stretch wrapping machine is a smart investment for logistics

Why a stretch wrapping machine is a smart investment for logistics

Blog Article

Discover the Advantages of Making Use Of a stretch wrapping machine for Effective Product Packaging Solutions

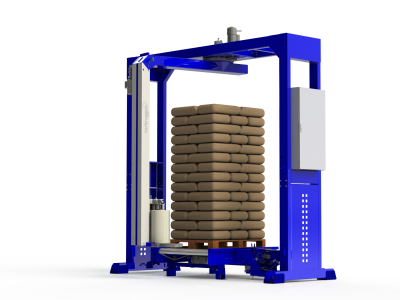

Worldwide of product packaging options, efficiency is crucial. Automation has actually yielded substantial improvements, such as the stretch wrapping machine. With its ability to wrap things securely and quickly using stretchable plastic film, it supplies a high level of precision and rate. It's not almost covering things, but likewise concerning minimizing labor expenses, minimizing waste, and maintaining aesthetic charm. So, what makes these machines a game-changer in the packaging market?

Comprehending the Capability of Stretch Covering Machines

Spearheading the product packaging industry, stretch wrapping machines improve the procedure of firmly product packaging things for transport or storage space. These sophisticated machines employ a basic yet efficient device, making use of an elastic plastic film that is wrapped around items, supplying security and defense. The products, commonly arranged on a pallet, are revolved as the movie is given, making certain a limited and safe and secure wrap.

The film's elasticity offers a double function: it firmly binds the items with each other, reducing the threat of damages because of movement, and it gives an obstacle against dust, dampness, and other potential hazardous elements. The transparent nature of the stretch movie allows for very easy recognition of the packaged items.

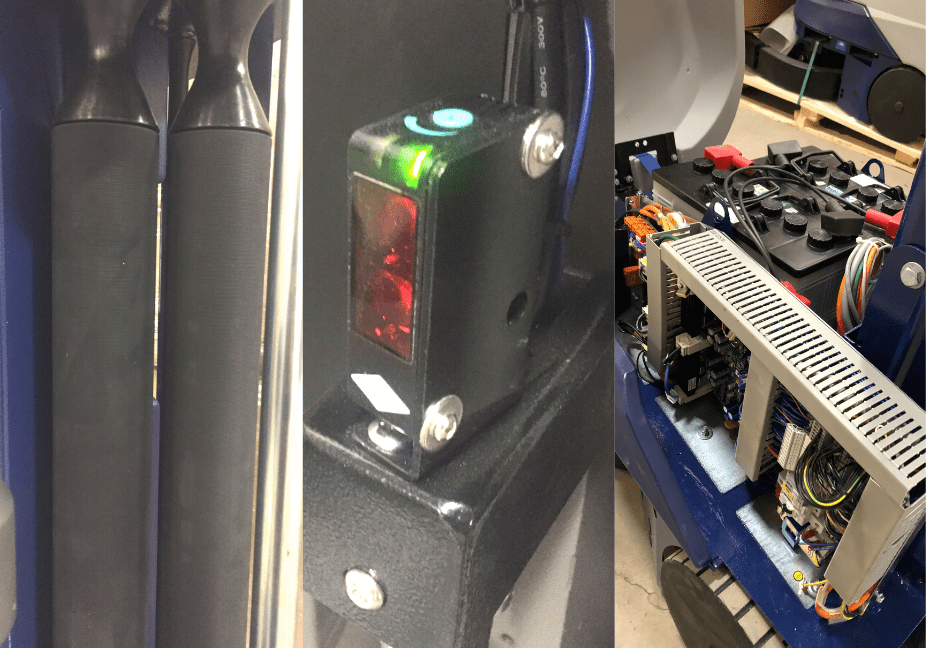

The equipments vary in their operation setting, with some being semi-automatic, requiring marginal human intervention, and others being fully automated, efficient in separately managing the whole wrapping procedure. No matter their mode, stretch covering machines are a keystone of risk-free and reliable packaging.

How Stretch Covering Machines Enhance Efficiency

Enhancing efficiency levels dramatically, stretch wrapping equipments improve the product packaging process with their automated capacities. These sophisticated equipments allow firms to cover a high volume of plans swiftly and efficiently, supplying a consistent wrapping result that hands-on methods just can not match. This rate and consistency convert straight into boosted productivity, allowing businesses to satisfy requiring supply timetables and customer expectations.

Additionally, stretch covering makers call for minimal human intervention. As soon as the machine is established up and the covering parameters are configured, the equipment can operate individually, releasing up employees to concentrate on other essential tasks. This automation not just lowers labor costs however likewise removes human errors, making certain the quality of wrapping stays regular.

On top of that, the use of stretch wrapping equipments often results in less downtime. stretch wrapping machine. With their robust layout and reliable operation, these machines are much less vulnerable to failures and upkeep problems, guaranteeing continuous workflow and boosted performance

Minimizing Material Waste With Stretch Covering Machines

While boosting efficiency, stretch wrapping machines additionally play a critical duty in decreasing material waste. The precision of these equipments makes sure that each package is covered with the specific amount of he said product needed, decreasing excess waste. This precision not only causes a visually pleasing and consistent plan, however additionally contributes substantially to environmental sustainability.

In significance, the use of stretch wrapping machines in a product packaging line is not just a step in the direction of effective efficiency, but additionally a jump towards environment-friendly methods by considerably reducing product waste.

Expense Reduction: A Key Advantage of Stretch Covering Machines

In enhancement to mitigating material waste, another substantial benefit of stretch wrapping makers is their possibility for expense reduction. These devices are reliable, calling for much less manual work for packaging products, thus lowering labor prices.

Moreover, stretch wrapping machines utilize less product to package goods firmly as compared to conventional wrapping approaches. This reliable use products not just reduces waste however likewise decreases expense on packaging materials.

The makers additionally minimize damage to products during transportation. With protected and strong product packaging, the threat of item damage decreases, decreasing the expenses linked with item returns and substitutes.

Finally, the speed and effectiveness of stretch wrapping makers can raise manufacturing prices. Faster product packaging times suggest that companies can package and ship even more products in less time, improving general efficiency.

Carrying Out Stretch Covering Machines in Your Product Packaging Refine

Provided the excellent advantages of stretch covering equipments, browse around here incorporating them right into your product packaging process can be a game-changing choice. An evaluation of the current product packaging procedure is needed to determine the excellent device kind and size.

Training team on maker operation is essential. This consists of understanding the equipment's performances, troubleshooting usual problems, and sticking to security standards. By doing so, services can ensure an effective, affordable packaging process, gaining the full advantages of their financial investment in stretch covering makers.

Final thought

Finally, stretch covering machines supply effective, cost-effective packaging remedies. They enhance performance and reduce waste by specifically wrapping things with elastic plastic film, meeting high-volume demands easily. These machines guarantee item security and defense, while also delivering visually pleasing bundles. For organizations aiming to optimize their packaging operations, this modern technology gives an effective path towards improved effectiveness and expense financial savings.

When the machine is established up and the wrapping parameters are set up, the device can operate individually, freeing up staff members to focus on various other important jobs.While find more enhancing efficiency, stretch wrapping makers likewise play an essential duty in decreasing material waste.Provided the outstanding advantages of stretch wrapping makers, incorporating them right into your packaging procedure can be a game-changing decision - stretch wrapping machine. By doing so, organizations can guarantee a reliable, cost-effective packaging procedure, reaping the full advantages of their financial investment in stretch wrapping devices

In verdict, stretch wrapping devices use reliable, affordable product packaging remedies.

Report this page